| Number of control axes | 3 axes |

| Minimum programming | 0.001mm |

| Maximum programming | ± 99999.999mm |

| Top speed | 30m / min |

| Feed speed | 0.001-15m / min |

| Manual continuous | One axis or simultaneous multi-axis |

| Screen saver function | Screen saver function |

| Program editing | Male / English, relative / absolute programming |

| Pre-reading function | Short line preprocessing 10,000 lines |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

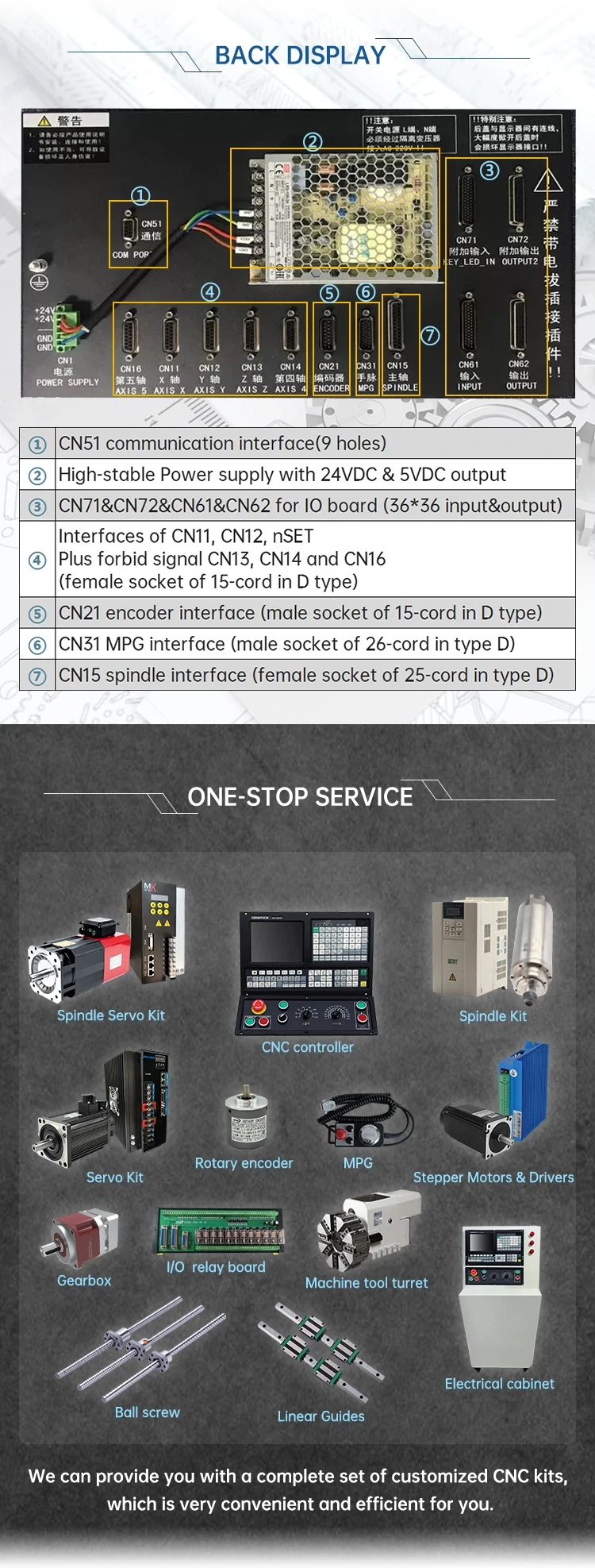

| Communication function | RS232, U disk interface |

| Program editing | Male / English, relative / absolute programming |

Tool functions: | 1)Tool length compensation |

| Password protection | Multi-level password protection |

PLC functions | 1)Two levels PLC programming, operation speed is 1.5μs/ step basic instruction; 4700 steps mostly, the cycle of the first level programming is 8ms. |

Multiple function:

It can realize the drilling/boring,roughing of roungroove / rectanglegroove ,finishing of full circle /rectangle, continous drilling of straight line /rectangle /arc etc.

FAQ

1. How long is the quality guarantee?

One year guarantee.

2. When can you receive our order?

All goods will be produced well within 5 to 7 workdays, except the customized products.

3. What is control mode for spindle axes?

There are dual analog voltage outputs(0~10V) for speed control of spindle axis. Our Modbus CNC also support Pulse speed spindle, also can use pulse to control speed of spindle servo system.

4. Does your cnc support ATC function?

Yes, our CNC lathe system can support most of turret, like Eletric turret,servo turret,counting turret,etc; We can edit special macro program & plc for special turrets also;

And our CNC milling system support Linear type , umbrella type, arm type, turret type tool magazines.

5.Could you supply total cnc system?

We can supply total cnc system, includes CNC controller, Spindle drivers & motors, Axes drivers & motors & related cables & kits, so you can plug and play.

If you have another question, pls feel free to contact us as below.