High Performance Good Quality 4 axis numerical control lathe controller with new English control panel ARM+DSP+FPGA usb cnc lathe complete kit

Number of control axes | 4 axes |

Minimum programming | 0.001mm |

Maximum programming | ± 99999.999mm |

Top speed | 30m / min |

Feed speed | 0.001-15m / min |

Manual continuous | One axis or simultaneous multi-axis |

Interpolation method | Straight line, arc, thread interpolation |

Tool offset | Length compensation, nose radius C compensation |

Spindle functions | Gear, dual analog control, rigid tapping |

Handwheel functions | Panel type, plug-in hand-held |

Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

Program editing | Male / English, relative / absolute programming |

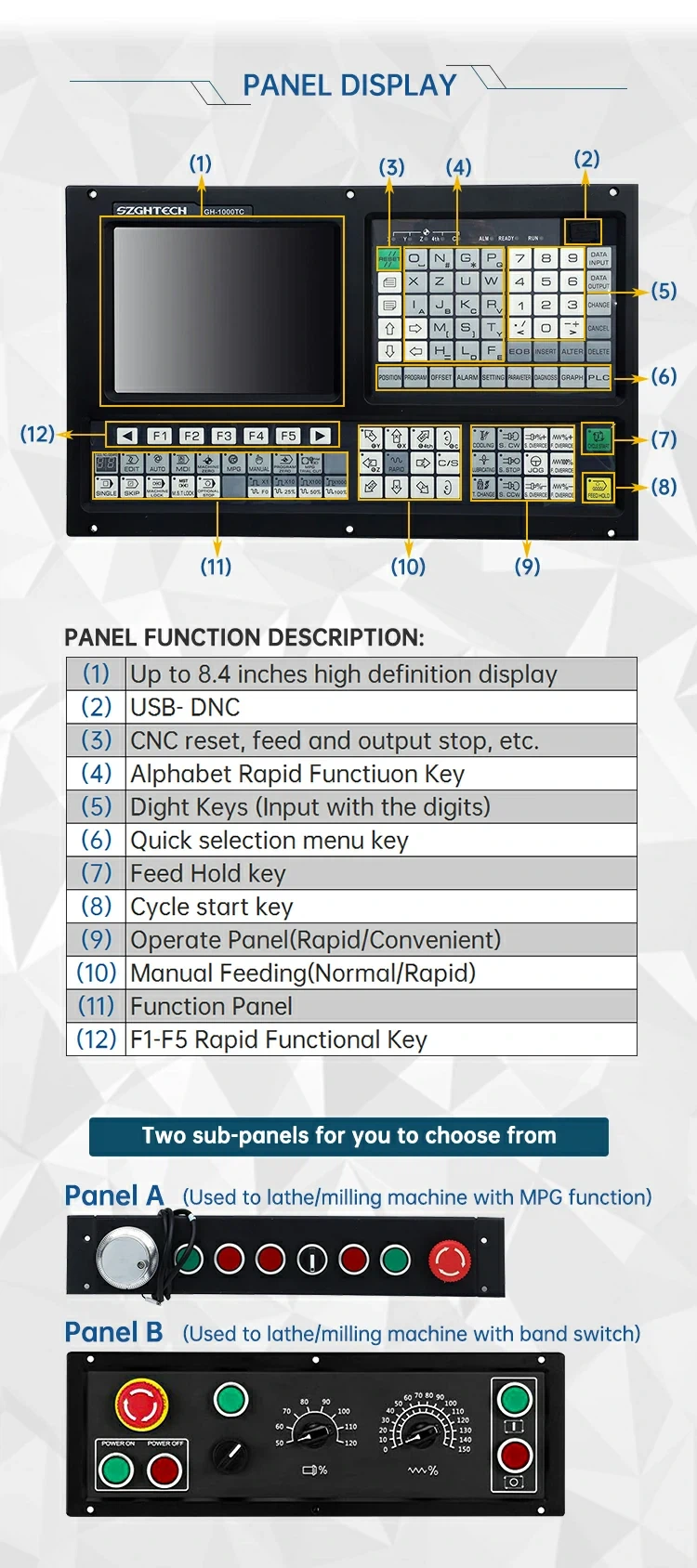

GH controller uses a high-performance dual-core CPU and ultra-large-scale programmable gate array integrated circuit chip FPGA to form the control core to realize μ-level precision motion control. The brand-new controller panel, equipped with an 800*600 dot matrix 8.4-inch true color LCD screen, coupled with a newly designed display interface, has been highly praised by many customers.

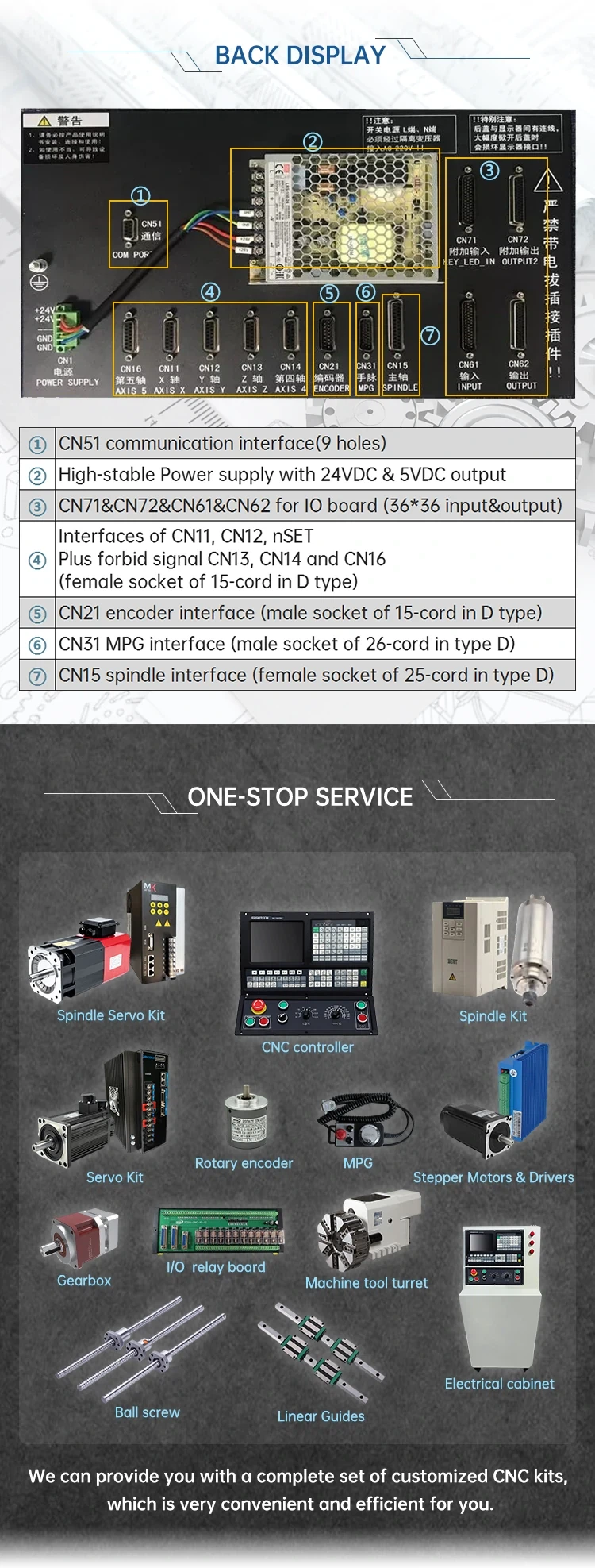

1) Support Dual analog voltage(0~10V) & C-axis for Spindle servo(M800)

2) Support Stepper/Increment/Absolute/EtherCAT/Powerlink Servo for Feeding Axes

3) Scanning Function & Auto Tool Setter/Probe

4) High anti-jamming switch power(100V-240VAC 50Hz/60Hz- >24VDC)

5) Two sub-panels for choose,Panel A for MPG function,Panel B for band switch

6) 64 mb memory,56 mb user store room

7) 32 bits ARM microprocessor+FPGA Technology

FAQ

Q1.Who are we?

A: We are based in Guangdong, which providing cnc total solutions&Robot arm, sell to Eastern Europe(20.00%), Mid East(20.00%), Southeast Asia(15.00%), Southern Europe(10.00%), South America(8.00%), North America(5.00%), Western Europe(5.00%), Eastern Asia(4.00%), Central America(4.00%), Northern Europe(4.00%), Africa(3.00%), Domestic Market(2.00%).

Q2. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q3. Do you have any MOQ (minimum order quality)limit?

A: Low MOQ, 1pc for sample checking is available.

Q4. How to proceed an order?

A: Initially, let us know your requirements or application. Besides, We quote according to your requirements or our suggestions. Thirdly, customers confirms the samples and places deposit for formal order. Finally, We arrange the production.

Q5. Is it acceptable to print my logo on the product?

A: Yes. Please inform us formally before our product and confirm the design firstly based on our sample.

If you have any other question about our cnc lathe controller kit, pls feel free to contact us as below.Any order requirement, pls do not hesitate, we must do good support to you! come on!