SZGH-H1850-B-6 Welding Robotic Arm MIG/MAG Welding

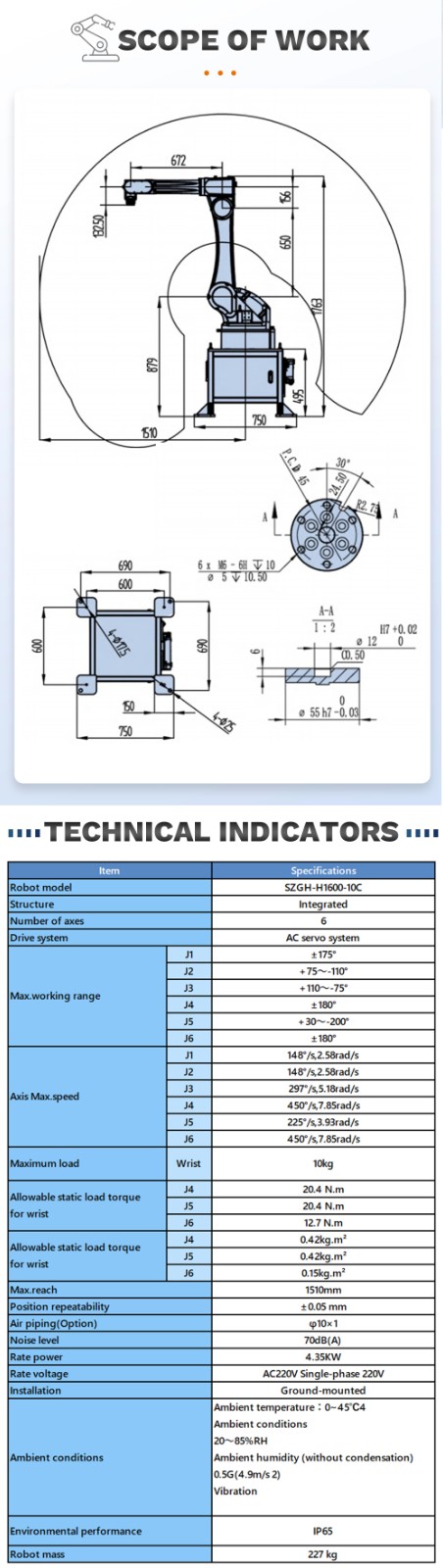

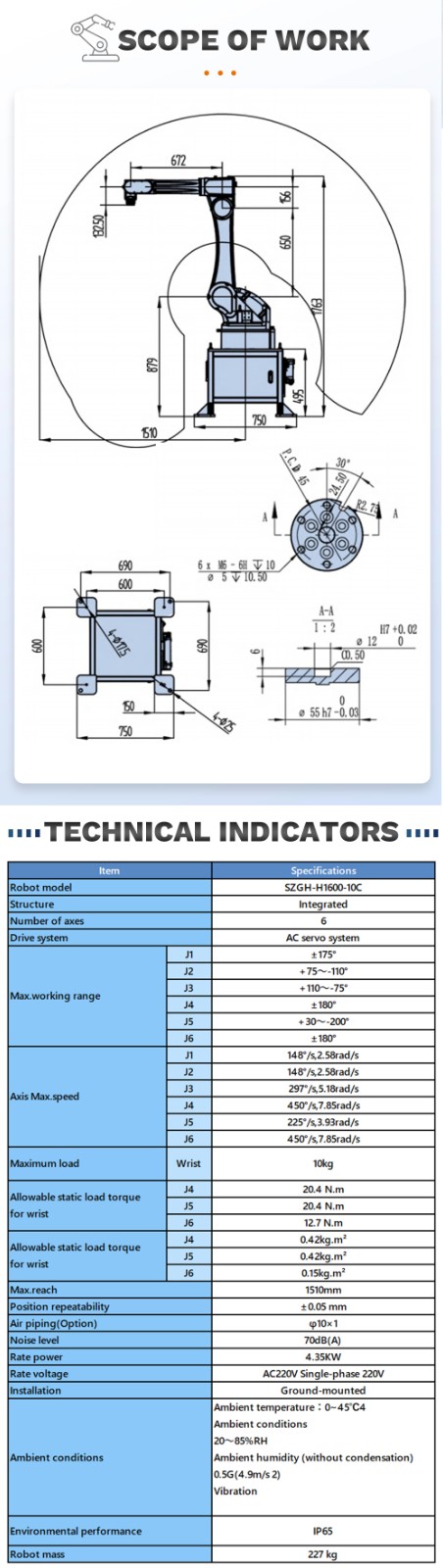

Number of axis::6 Axis

Product name:ROBOT ARM

Reach::1850mm

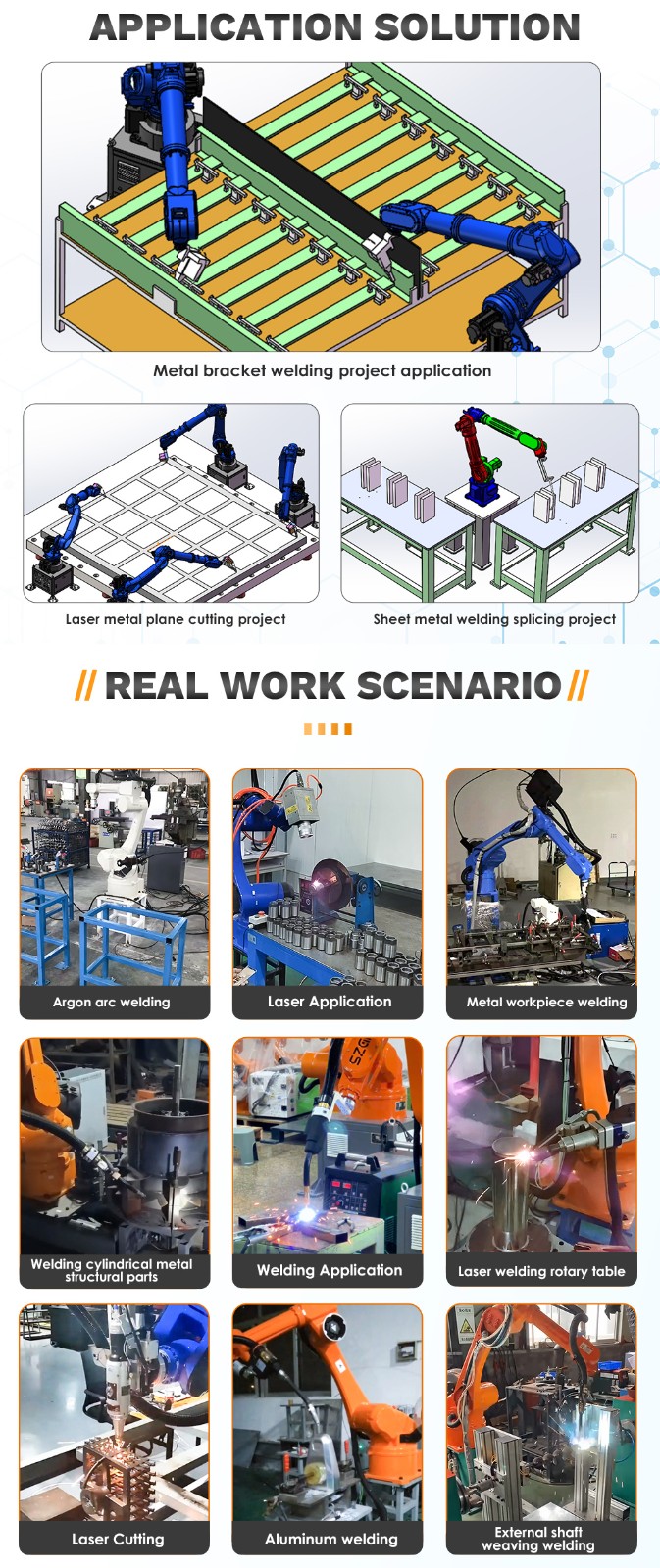

Function::Tig welding , laser welding

Ambient temperature: -:-5℃~45°C

Payload::6KG

Repeatability::±0.05mm

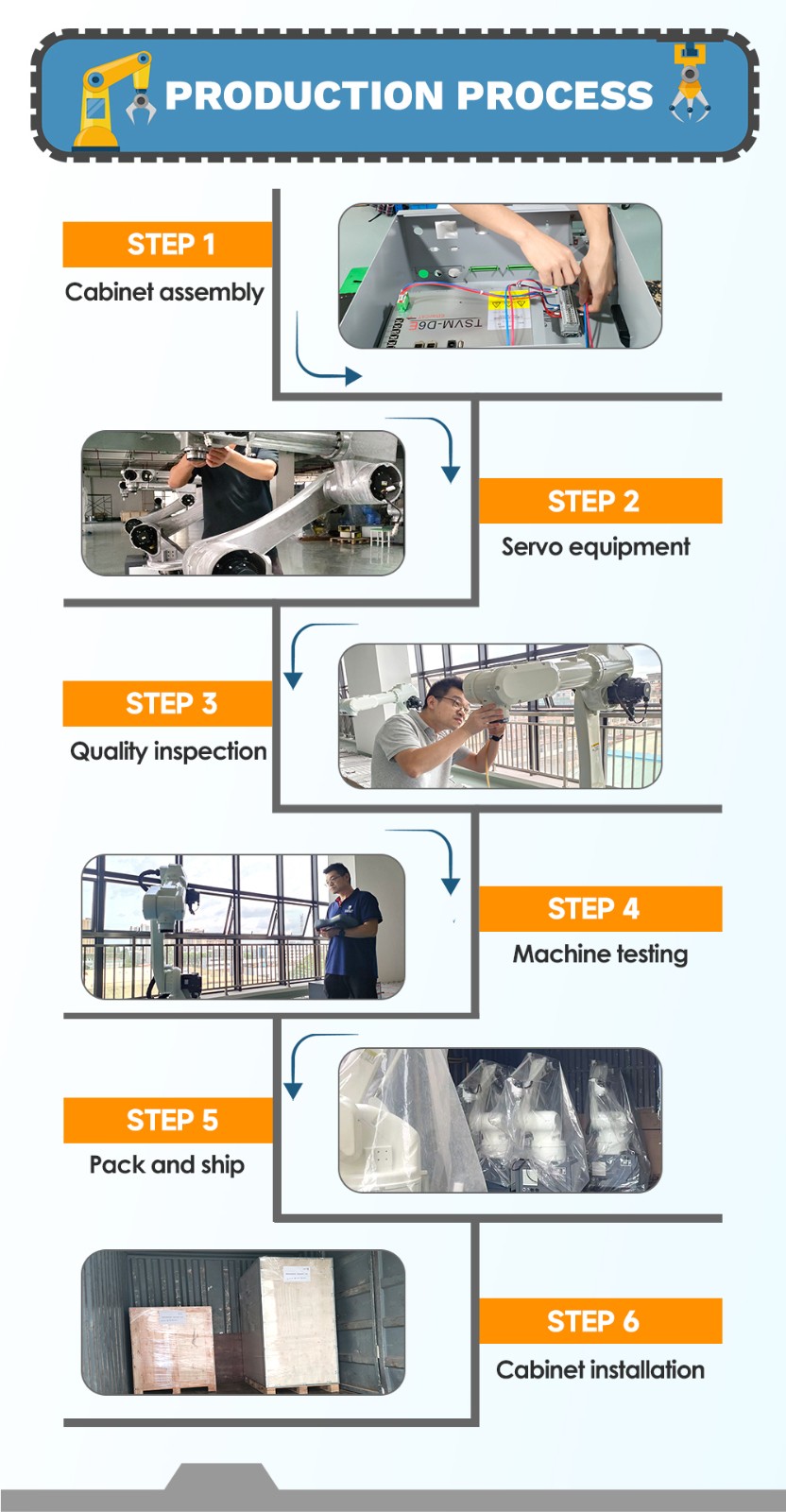

Condition:New

Video outgoing-inspection:Provided

Applicable Industries:Manufacturing Plant

Warranty:1 Year

power(w):1kW

voltage:220V

Drive Type:servo-electric

Ingress Protection:ip65

place of origin:CN;GUA

brand name:SZGH

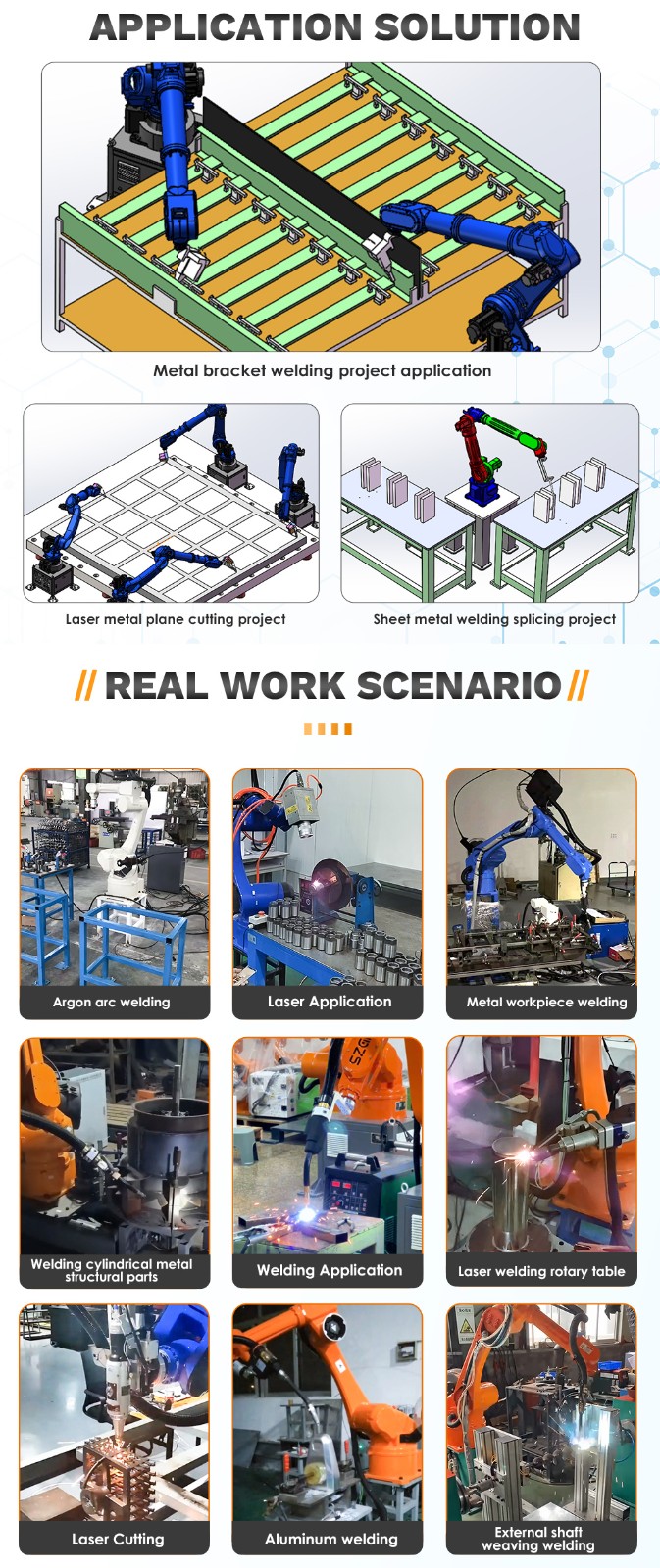

application:welding

production capacity:500 set per month

dimension(l*w*h):160*1450*190

weight (kg):205

Number of Jaws:1

Send Inquiry