SZGH-B2100-F-4

Product Description

Payload | 100kg |

| Structure | Articulated |

Axes | 4-11 Axes |

| Reach | 2100mm |

| Weight | 650kg |

| Mounting Type | Horizontal |

| Ambient Temperature | 5℃~45℃ |

| Production Capacity | 1000 Sets/Month |

Application | Materials handling, parts transfer, palletizing, deburring &cutting |

Special Service | 1. We can customize the standard color as you need! |

SZGH SZGH-B2100-F-4 4 axis handling robot is specially developed for complex applications with multiple degrees of freedom. Its maximum load is up to 100kg and its arm span is 2100mm.

Product parameter(specification)

| Arm | Axis 1 | Axis 2 | Axis 3 | Axis 4 |

| Max motion range | ±175° | +80°/-25° | +80°/-25° | ±360° |

| Max speed | 60°/sec | 148°/sec | 148°/sec | 148°/sec |

Maintenance of The Handling Robot

A handling robot is a high-tech piece of equipment that requires regular maintenance to ensure that it continues to work efficiently. Here are a few key steps to maintain a handling robot:

1.Regular cleaning: When the robot is working, it will often be exposed to a variety of different substances, such as dust, grease, water, debris, etc., which will accumulate on the surface and mechanical parts of the robot. Therefore, it is very important to clean the robot regularly to keep it in working condition and extend its life. You can use some conventional cleaning methods such as vacuuming, wiping, brushing, etc.

2.Check the robot sensors: Robot sensors are the core component that controls the robot's movements, so it is essential to check regularly that they are working properly. You can check that the sensors are responding correctly by triggering them manually, or by using special test tools.

3.Regular replacement of parts: During the use of the robot, mechanical parts, transmission parts and electronic components may be damaged or worn, which will lead to the performance of the robot to deteriorate, so parts need to be replaced regularly. Before replacing a part, you need to make sure that you select the correct part and follow the instructions provided by the manufacturer.

4.Software upgrades: Over time, problems or vulnerabilities may occur with the robot's software, which can cause the bot to not work properly. Therefore, the robot's software needs to be upgraded regularly to ensure that the robot's functionality is updated and improved.

5.Regular maintenance: In addition to regular replacement of parts, regular maintenance of the robot is also required to ensure that the robot is operating in the best condition. Maintenance may include changing the oil, calibrating the robot, replacing the filter, and more.

These are some of the basic steps to maintain a handling robot. Please note that the specific maintenance steps may vary depending on the model, usage, and manufacturer's requirements of the robot, so it is best to understand the more detailed maintenance requirements according to the robot's instruction manual.

Main Applications

1. Materials Handling

2. Parts transmission

3. Stacking

4. Deburring

5. Cutting

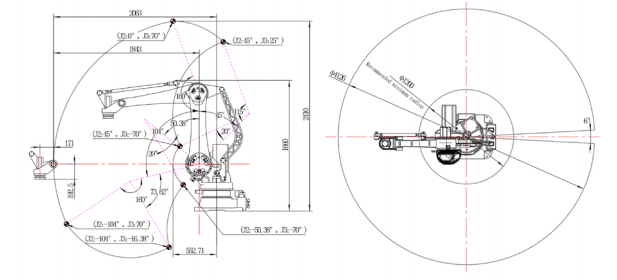

Robot Motion Range

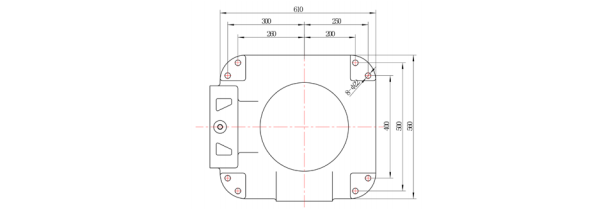

Robot Base Installation