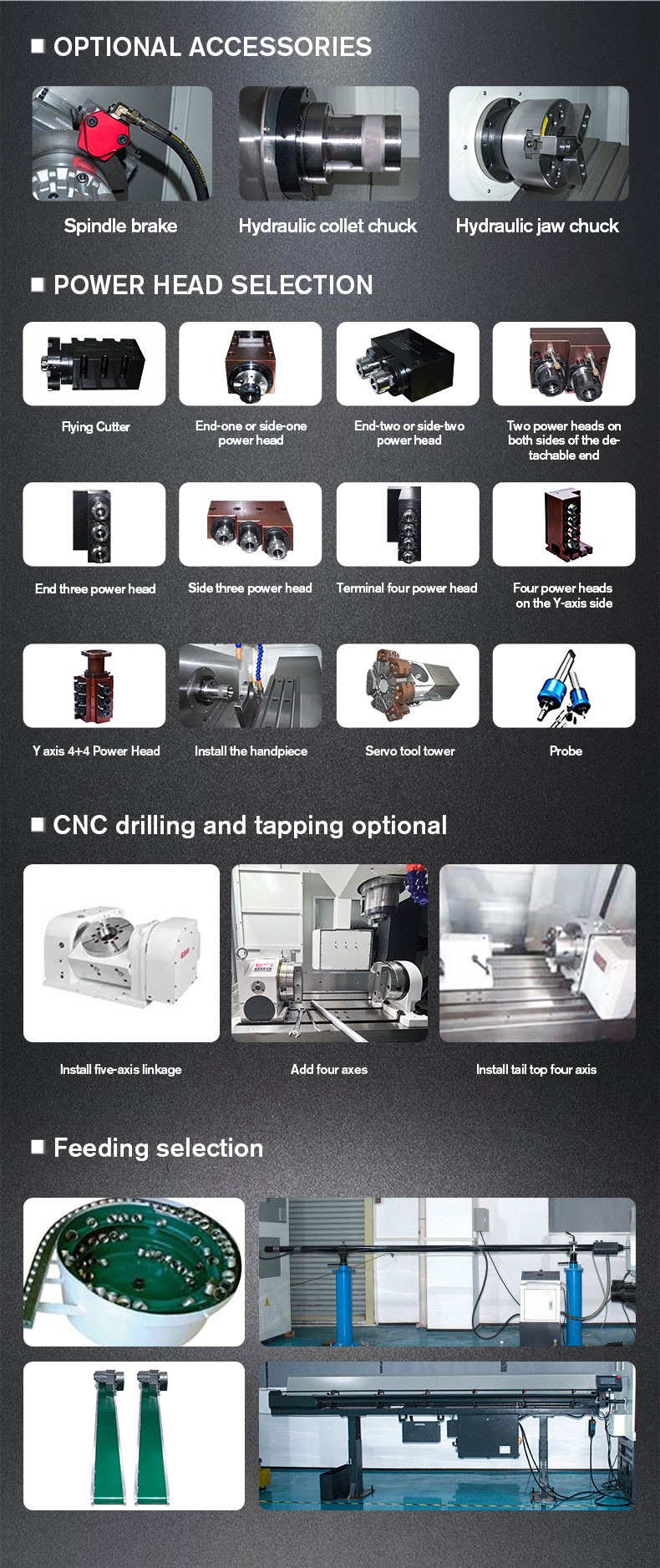

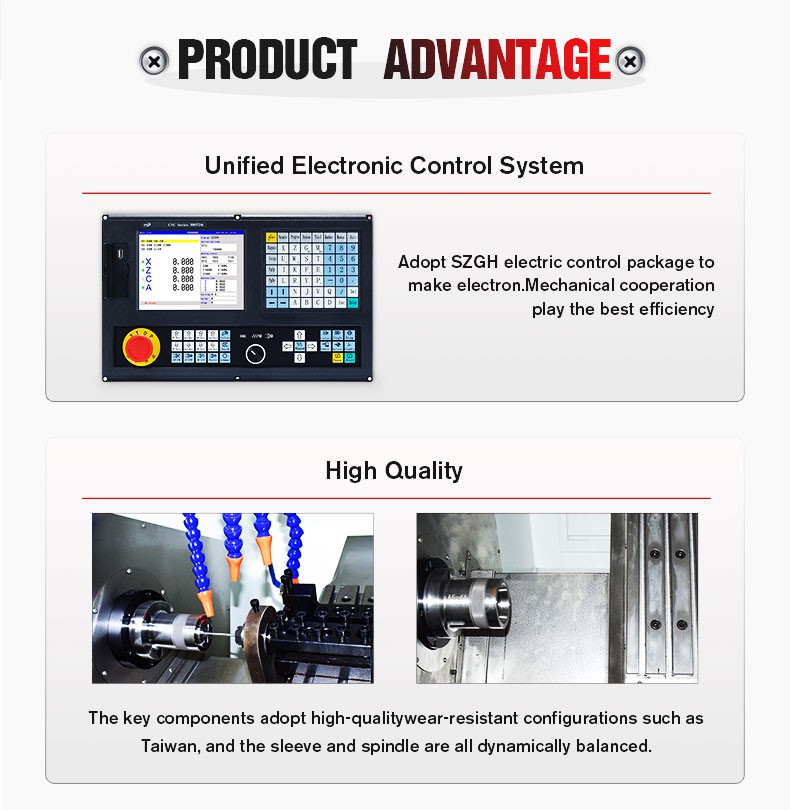

SZGH-25 mini CNC lathe adopts an advanced numerical control system, which can realize precise processing control. It has a highly rigid structure, which ensures stability and deformation resistance during processing, thus achieving high-precision machining. The lathe is also equipped with automatic tool changeover and automatic loading functions, which improve production efficiency.

The SZGH-25 machine tool excels in precision and can meet high standards of product precision requirements. Through advanced control technology and strict processing, the SZGH-25 is able to control the tolerance within a very small range, thereby ensuring that the quality of the product always meets the design standards and customer needs. This machine tool is not only suitable for processing precision parts such as precision bearings, threaded rods, connectors, etc., but also can handle a variety of materials and has a wide range of adaptability. Its excellent processing capabilities enable it to be used in multiple industries, especially in aerospace, automobile manufacturing, precision instruments and other fields, to meet the production needs of high precision and high reliability. The stability and efficiency of the SZGH-25 enable the production process to minimize errors and improve production efficiency, while also helping to reduce production costs and ensure that the quality and performance of the final product remain consistent.

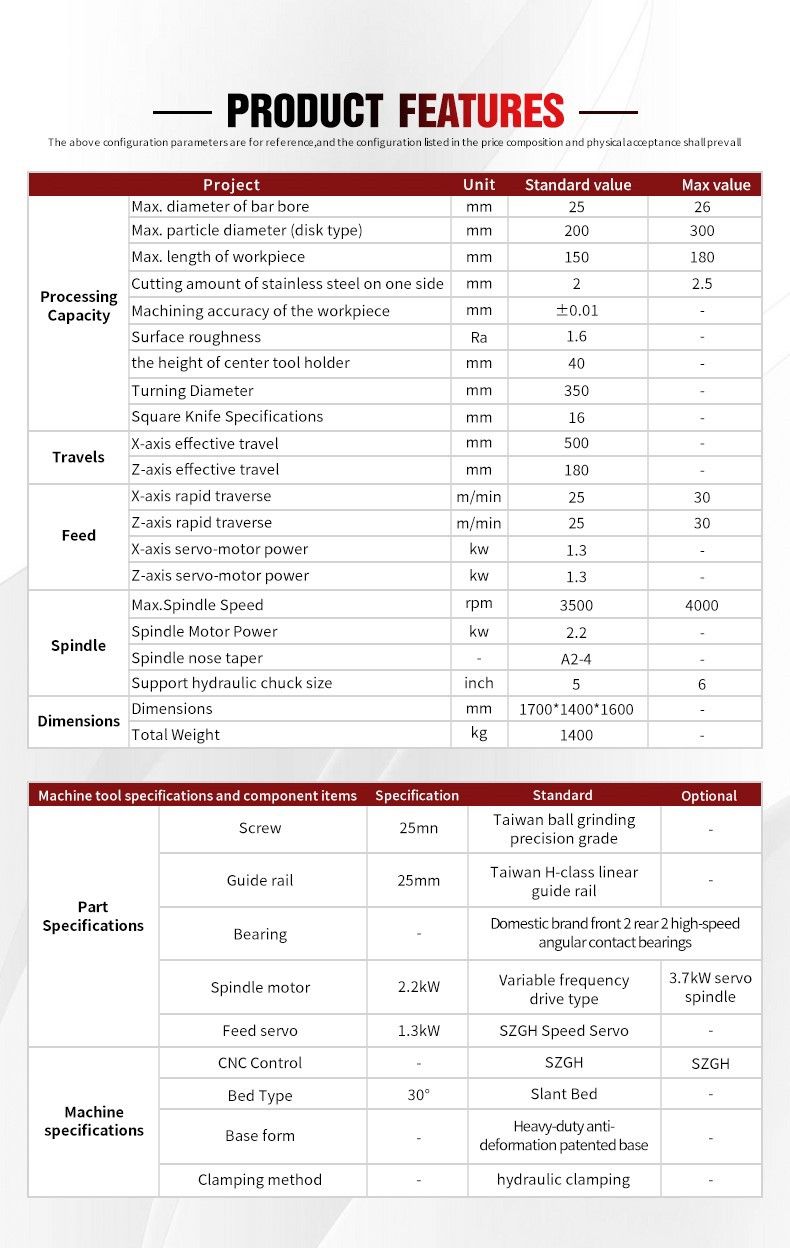

The SZGH-25 is a high-performance 2-axis mini CNC turning machine for a wide range of machining needs. SZGH-25 lathe is widely used in the mass production of copper, iron, aluminum, stainless steel, and other bar materials within 25mm. At the same time, it is also suitable for automatic feeding and mass production of forged parts and other pellets within 50mm.

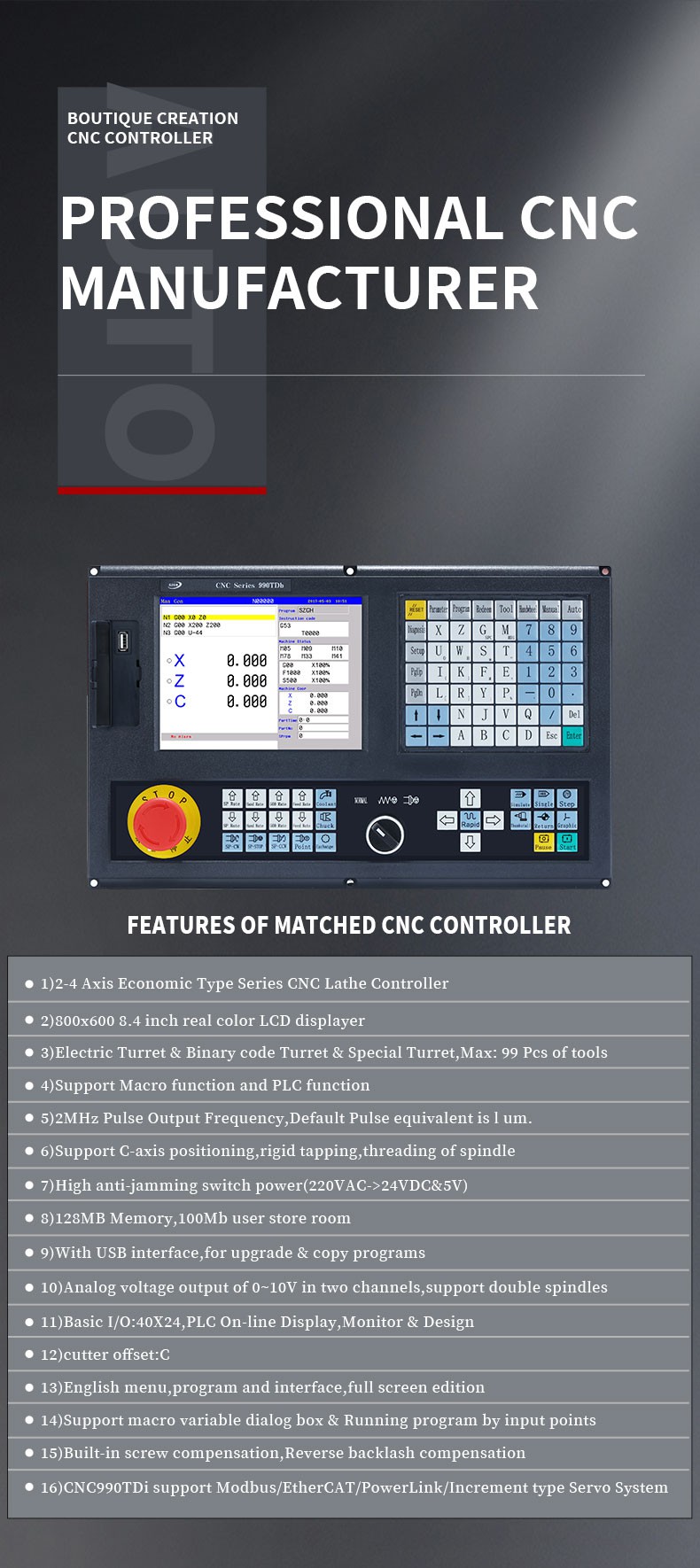

1.Our 2-axis lathe controller is built for high-performance motion control, delivering both speed and precision to ensure accurate tool positioning and fine machining. With advanced control algorithms, it enables the production of complex shapes and tight tolerances, making it ideal for a wide range of materials and machining tasks. The system's ability to manage precise cutting processes reduces material waste, improves efficiency, and ensures high-quality output.

2.Additionally, the controller is scalable and flexible, supporting various programming methods and the easy adjustment of processing parameters such as feed rates and cutting speeds. This adaptability allows it to meet different machining requirements, whether for small custom jobs or large-scale production runs. Its rich interface and communication capabilities make it simple to integrate with other devices, streamlining workflows and enabling seamless data exchange across machines.

3.Safety and reliability are integral to the design of our 2-axis lathe controller. With built-in features such as emergency stop buttons, overload protection, and error detection mechanisms, operators are protected from potential hazards, while the system ensures minimal downtime and maximum operational longevity. These advanced safeguards help prevent costly damage to equipment and maintain a safe working environment.