Product Description

2-axis CNC Vertical Turning Lathe - Model SZGH-25 (The CNC Controller Model is SZGH-CNC990TDb--2)

Our company is proud to introduce a brand new 2-axis vertical lathe machine, model SZGH-25. As a company focusing on CNC systems, machines, and robotic arms, our team has developed this high-performance, high-precision lathe machine with rich experience and a professional team of engineers.

Performance & Characteristics:

1) High-performance spindle: The SZGH-25 is equipped with a high-performance spindle that offers a wide speed range to meet a variety of machining needs. The powerful power output of the spindle ensures cutting efficiency and machining precision

2) Precise machining capability: The SZGH-25 2-axis CNC vertical turning lathe machine is known for its outstanding precision. With the help of an advanced CNC control system and high-precision transmission device, it can achieve accurate micron-level machining, ensuring the quality of parts and one

3) Multifunctional turret: This lathe machine is equipped with a set of multifunctional turrets that provide multiple tool positions, making quick changes of cutting tools and multiple machining operations possible. In this way, you can choose the right tool according to different machining requirements

4) Advanced control system: SZGH-25 adopts an advanced CNC control system with a user-friendly interface and powerful functions. Operators can easily set up machining programs, adjust parameters and monitor machining processes to improve work efficiency and productivity

5) High-rigidity structure: Our lathe machine adopts a high-rigidity bed structure, which ensures a stable machining process and excellent cutting performance. This structural design allows the machine to maintain high accuracy and reliability even at high speeds and under heavy loads

6) Safety and reliability: Safety is always our top priority, and the SZGH-25 CNC vertical turning lathe machine is equipped with safety protection devices such as an emergency stop button, overload protection, and an emergency stop system. These measures ensure timely downtime in case of emergency and protect operators and equipment.

7) Customizable options: We offer options that are customized according to customer needs to ensure that our machines fully meet your specific needs. Whether it's size, configuration, or other functional requirements, we're here for you.

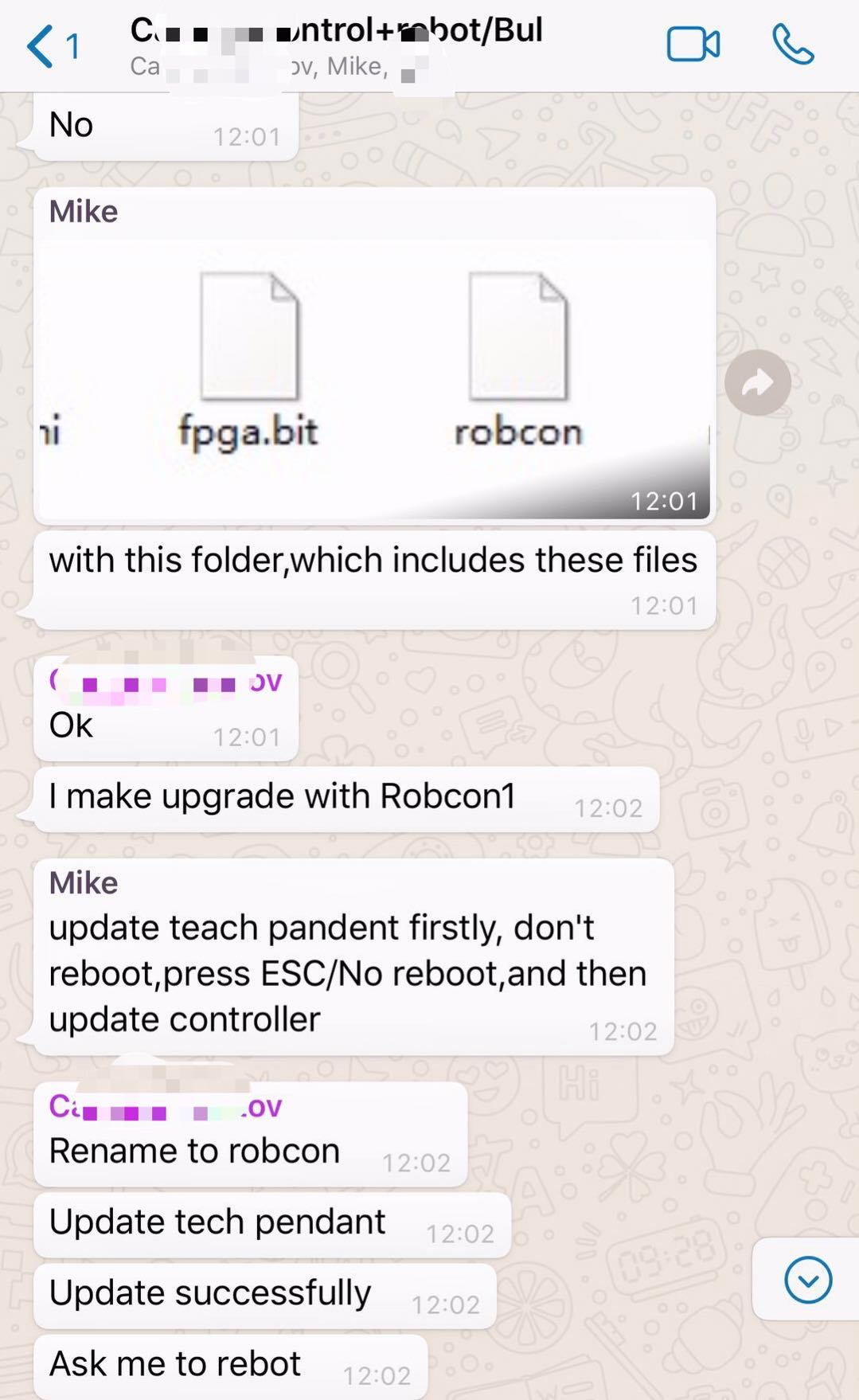

SZGH-CNC990TDb-2

1. Our 2-axis CNC vertical turning lathe machine controller is a high-performance device. It provides high-precision motion control and powerful features to ensure that your lathe machine achieves superior performance and precision during machining.

2. Compared to our peers, our 2-axis lathe controller has unique characteristics. First of all, it adopts advanced CNC technology and reliable control algorithms to ensure stable motion control and excellent processing results. Secondly, we focus on user experience, the controller interface is simple and intuitive, and the operation is convenient so that the operator can quickly get started and operate the machine efficiently.

3. This 2-axis lathe controller delivers outstanding performance. It enables high-speed, high-precision motion control to precisely control the position of the tool and the cutting process, enabling fine machining and complex shapes.

4. Our 2-axis lathe controllers are also scalable and flexible. It supports a variety of programming methods and adjustment of processing parameters and can be customized according to different processing needs. At the same time, it also has rich interface and communication functions, which is convenient for linkage and data transmission with other devices.

5. A focus on safety and reliability is an important feature of our 2-axis lathe controllers. We employ advanced safety measures and protection features such as emergency stop buttons, overload protection, and error detection mechanisms to ensure the safety of operators and equipment.

Machine Features

|

|

| Spindle Self-made high-speed matching bearing unit spindle, using angular contact high-speed bearings, normal speed 3500/min is suitable for large cutting-volume processing. The clamping method can be used according to different occasions of customers. Changed from hydraulic to pneumatic clamping, if high-speed high-gloss requirements are required, a 6000-rpm high-speed electric spindle can be selected. |

Rotary Cylinder The standard configuration adopts a hydraulic rotary cylinder to make the clamping force stronger, more stable, and has a longer service life. It can be replaced by pneumatic clamping according to the actual situation |

|

|

|

|

| Ball Screw Adopt Taiwan Dinghan 25 ball grinding precision screw rod. |

Machining of long shaft workpieces It can realize the processing of a 120mm long workpiece with a nozzle holder. |

Linear Guides Adopt Taiwan Dinghan 25 linear guide rail |

|

|

Company Profile

1. Professional Supplier: We are a supplier focusing on CNC systems, machines, and robotic arms. With years of industry experience and a professional team of engineers, we are committed to providing high-quality automation equipment and solutions.

2. Global sales network: Our products are sold all over the world, and we have established a solid cooperative relationship with global customers. No matter what country or region you're in, we offer comprehensive support and services to ensure your automation needs are met.

3. Extensive experience: We have extensive experience in providing customized automation solutions to customers in many industries. Whether in manufacturing, the automotive industry, or aerospace, we offer reliable and innovative solutions tailored to the specific needs of our customers.

4. High-Quality Products: Our products are known for superior quality and reliability. We work with world-renowned suppliers to select high-quality components and materials to ensure that the automation equipment we supply excels in terms of performance and durability.

5. Customer satisfaction: Customer satisfaction is the goal that we always pursue. We are committed to understanding the needs of our customers and providing a full range of technical support and after-sales service. Our customers trust us and with me

Delivery and after-sales service

FAQ

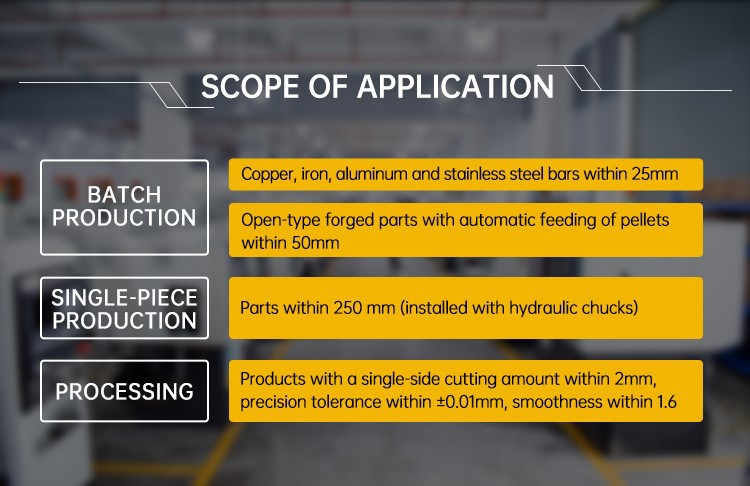

Q1: What types of machining tasks is this 2-axis CNC vertical turning lathe machine suitable for?

A1: Our 2-axis lathe machine is suitable for all kinds of small and medium-sized workpiece machining tasks, such as shaft parts, thread machining, hole machining, etc. It provides high precision and stable machining performance and is suitable for a variety of industries, such as manufacturing, auto parts manufacturing, and aerospace.

Q2: How accurate is the machining of this 2-axis CNC vertical turning lathe machine?

A2: Our 2-axis lathe machine has excellent machining accuracy. It adopts advanced numerical control technology and a high-precision transmission device to achieve micron-level machining accuracy. Our team of engineers will carry out strict accuracy calibration during the commissioning and testing phase of the equipment to ensure the stability of the machine.

Q3: Does this 2-axis lathe machine have an automation function?

A3: Yes, our 2-axis lathe machine has certain automation functions. It is equipped with an advanced CNC control system, which can realize automatic machining operations and program control. You can pre-set machining programs, process parameters, toolpaths, etc. for efficient and precise automated machining processes.

Q4: Is this 2-axis lathe machine easy to operate and maintain?

A4: Yes, our 2-axis lathe machine is simple in design and easy to operate. It features a user-friendly interface and an intuitive operator panel, allowing operators to quickly get started and master operating skills. In addition, we provide detailed user manuals and technical support to ensure that you can easily carry out equipment maintenance and upkeeping.

Q5: Does this 2-axis lathe machine provide after-sales service and technical support?

A5: Yes, we provide comprehensive after-sales service and technical support. Our team will provide you with equipment installation and commissioning, operator training, maintenance, and spare parts.

Welcome to send us an inquiry, we will be happy to provide you with the best solution!