2 axis cnc lathe controller for for Planer Type Milling Machine

Function:

1)ATC function: Electric Turret/Binary Turret/Servo Turret/Special Turret

2)Threading Cycle: Following Mode/Interpolate Mode

3) Scanning Function & Auto Tool Setter/Probe

Application:

It can able to logically process programs with control codes or other symbolic instructions, decode them by the computer, so that the machine tool executes the prescribed actions, and the blanks are processed into semi-finished parts through tool cutting, which greatly improves mold processing Productivity

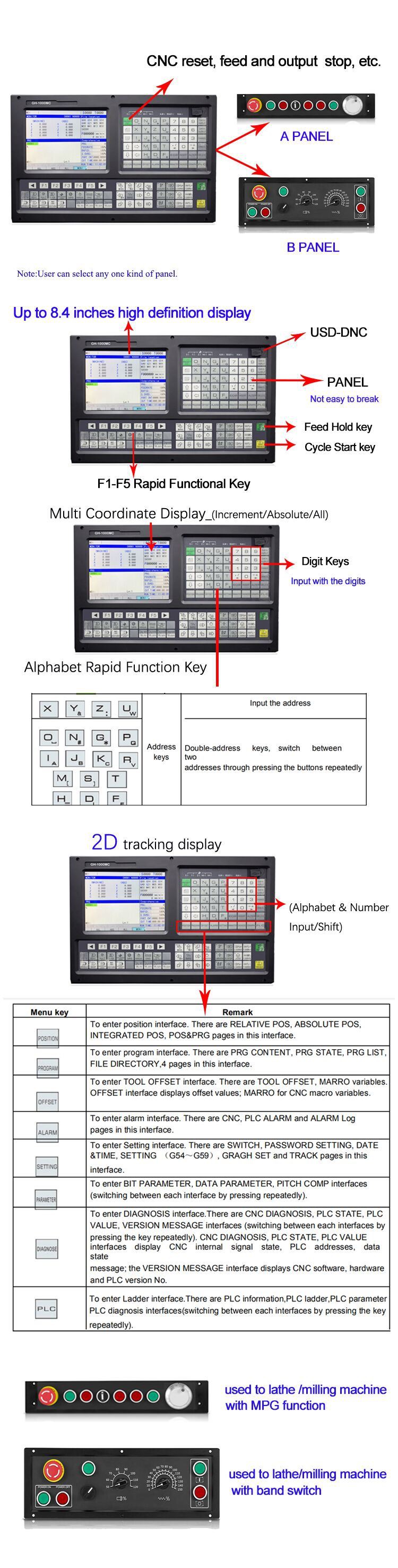

The 1000TC-2 lathe CNC system is a very popular control CNC product in the 1000TC series.

It adopts high-performance dual-core CPU and ultra-large-scale programmable gate array integrated circuit chip FPGA to form the control core to realize μ-level precision motion control. The new panel structure is equipped with an 800*600 dot matrix 8.4-inch true color LCD screen.

It can be equipped with a multi-turn 17-bit absolute encoder servo motor or incremental encoder motor, and can be programmed to complete the outer circle, end face, slotting, taper, arc, thread and other processing.

If you have another question, pls feel free to contact us as below!

FAQ

Q:What two axis are used by a lathe controller?

A:The two axises used on a CNC lathe are:

X - Cross

Z - Longitudinal

Q: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable. The material, color, style can customize, the basic quantity we will advise after we discuss.

Q: Can we use our own logo?

A: Yes, we can print your private logo according to your request.

Q: How many different types of products your company manufactures?

A: Now we have more than 300 products. We have a strong advantage of OEM, just give us the actual products or your idea that you want, we will manufacture for you.

Q: How long is your delivery time?

A: The general delivery time is 4-6 days after receiving your order confirmation. , if we have the goods in stock, it will only take 1-2 days.

Q: Do you provide sample? Is it free?

A: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.