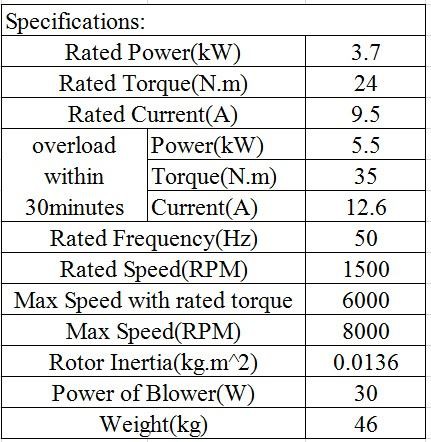

3.7Kw Servo Spindle Motor-The model is SZGH09-2-24-3.7/5.5-4-1500: 3.7Kw,24NM,max speed 8000RPM,rated speed1500RPM 380V.

This servo spindle motor has the following functions and characteristics:

1. Power Output: With a power rating of 3.7kW, it provides sufficient power to drive the machine, making it suitable for various applications that require moderate power.

2. Voltage Compatibility: It supports both 220V and 380V, allowing it to be compatible with different power supply configurations and environments, providing flexibility and adaptability.

3. Servo Control: Equipped with servo control technology, it offers precise position control and speed regulation capabilities, enabling accurate machining and motion control.

4. Spindle Drive: Specifically designed for machine spindles, it delivers high-speed rotation and torque output, making it suitable for applications that require high rotational speed and load capacity.

5. Energy Efficiency: Utilizing advanced motor design and control algorithms, it exhibits high energy efficiency, maximizing the conversion of electrical energy into mechanical energy, thus reducing energy consumption and heat generation.

6. Reliability and Durability: Manufactured with high-quality processes and selected materials, it ensures reliability and durability, allowing stable operation even under prolonged and high-load conditions.

7. Integration: It supports seamless integration with other equipment and control systems, facilitating its use in automated production lines or workstations, enabling synergistic operation and efficient production.

|

|

▶ Features:

High-Speed Precision Machining: Constant power output over 4000RPM,stable ratoting speed,ensure finish;

Strong Applicability: Match for CNC System , PLC etc.

Powerful Development : Custome Manufacturing.

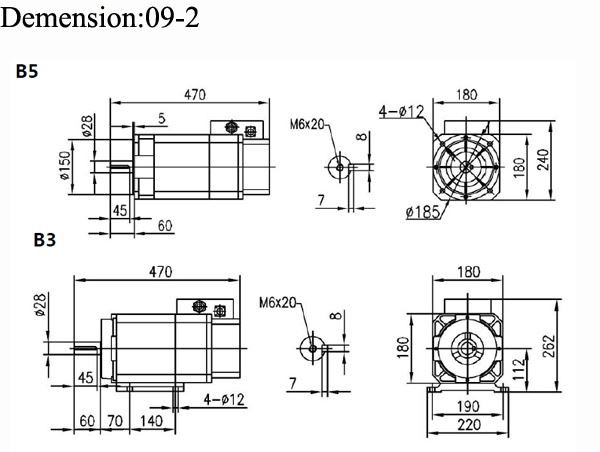

Dimension of Spindle Servo Motor can be customized.

Application: CNC Lathe Machine,CNC Milling Machine,CNC Machine Center,CNC Grinding Machine & Other Speical Machine.

|

|

Application Of The Servo Spindle Motor

Servo spindle motors are widely used in the following fields:

1. Machine tooling: Servo spindle motors play a key role in machine tooling, driving the spindle for tasks such as milling, drilling, cutting, and threading. Its high-speed rotation and high torque output capabilities, as well as precise position and speed control, make it ideal for high-precision and efficient machining.

2. Automated production line: Servo spindle motors can be used for various workstations and equipment on automated production lines, such as assembly lines, handling robots, and material handling systems. Its high-speed motion and precise control characteristics meet the need for fast, accurate, and reliable

3. Woodworking processing: In the woodworking industry, servo spindle motors can be used to drive woodworking machinery, such as wood cutting machines, woodworking engraving machines, and woodworking milling machines. Its high speed and torque output, as well as precise position and speed control, facilitate delicate woodworking and carving tasks.

4. Stone processing: In the stone industry, servo spindle motors are often used in equipment such as stone cutting machines and stone engraving machines. Its high speed and high torque output capability, combined with precise control, enable efficient, precise, and consistent stone processing.

Features and characteristics of servo spindle motors include:

1. High-speed rotation: Servo spindle motors have the ability to rotate at high speed, which is suitable for applications that require fast machining and high-speed motion.

2. High torque output: It is able to provide high torque output to cope with the load and resistance applied to the spindle, ensuring stable machining and motion performance.

3. Precise position and speed control: The servo spindle motor adopts servo control technology, which can achieve precise position and speed control to meet the requirements of high-precision machining.

4. High energy efficiency: The servo spindle motor adopts advanced design and control algorithms, with high energy efficiency characteristics, maximizing the conversion of electrical energy into mechanical energy, reducing energy waste and heat generation.

5. High reliability and durability: High-quality manufacturing processes and material selections ensure product reliability and durability.

Company Profile

We are a leading supplier of CNC systems with a strong track record of exporting our products worldwide. Our company specializes in the production of CNC controllers, servo motors and drives, servo spindle motors and drives, as well as a wide range of machine tools and robot arms.

Here are the characteristics and advantages of our company:

1. Extensive Export Experience: With our rich export experience, we have successfully penetrated global markets and established long-term partnerships with clients around the world. Our products have been widely recognized and appreciated for their quality and reliability.

2. Comprehensive Product Line: We offer a comprehensive range of CNC system solutions, covering everything from controllers to motors and drives, as well as complete machine tools and robot arm systems. Our diverse product portfolio allows customers to find all the necessary components from a single source, simplifying their supply chain management.

3. Quality and Reliability: We are committed to delivering products of the highest quality. Our products undergo rigorous testing and inspection processes to ensure they meet or exceed industry standards. We work with reliable suppliers and employ advanced manufacturing techniques to produce durable and reliable products.

4. Technological Innovation: We stay at the forefront of CNC technology advancements and invest in research and development. Our team of experienced engineers and technicians continuously strive to innovate and improve our products, offering cutting-edge solutions to meet the evolving needs of our customers.

5. Customization Capabilities: We understand that each customer has unique requirements. We offer customization services to tailor our products to specific needs, ensuring optimal performance and functionality. Our team works closely with customers to understand their challenges and provide tailored solutions.

6. Customer Service Excellence: We pride ourselves on delivering exceptional customer service. Our dedicated team provides comprehensive support throughout the entire sales process, from consultation to installation, training, and after-sales service. We prioritize customer satisfaction and ensure timely, professional, and friendly support.

FAQ

Q1: When can I get the quotation?

A1: We usually quote within 3 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q2: What is your terms of delivery?

A2: EXW, FOB, CIF, etc.

Q3: What is a servo spindle motor?

A3: A servo spindle motor is a special type of motor used to drive the machine tool spindle for machining tasks. It has high revs and high torque output capabilities, as well as precise position and speed control.

Q4: What is the difference between a servo spindle motor and an ordinary motor?

A4: Compared with ordinary motors, servo spindle motors have higher speed, torque, and precise control capabilities. They usually employ servo control systems that enable precise position and speed adjustment to meet the requirements of high-precision machining.

Q5: What are the application areas of servo spindle motors?

A5: Servo spindle motors are widely used in machine tool processing, automated production lines, woodworking processing, stone processing, and other fields. They play an important role in scenarios that require high-speed rotation, high loads, and precise control.

Q6: How to choose the right servo spindle motor?

A6: Selecting the right servo spindle motor needs to consider several factors, including required power, voltage requirements, speed range, torque output, control mode, etc. It is best to consult a professional supplier or engineer to determine the motor model that best suits the needs of your specific application.

Q7: What are the advantages of servo spindle motors?

A7: The servo spindle motor has the characteristics of high-speed rotation, high torque output, and precise control, which can realize high-precision and high-efficiency machining. Its servo control system enables it to have excellent position and speed adjustment capabilities to adapt to various complex process requirements.

Q8: What should I pay attention to in the maintenance and care of the servo spindle motor?

A8: For the maintenance and care of servo spindle motors, the guidelines and recommendations provided by the manufacturer should be followed. This typically includes regular cleaning and lubrication, checking the robustness of electrical connections, and regularly calibrating and testing the performance of the servo control system.

Any questions or are interested, please contact me at any time.